Safety and Efficiency in Manufacturing with ULA

Request a DemoClient

A manufacturing enterprise with an extensive network of production and warehouse facilities across Ukraine, focusing on operational efficiency and production process safety.

Challenge

The enterprise needed to improve safety, process control, and efficiency management. Key challenges included:

- Unauthorized access to critical zones.

- Low staff productivity.

- Lack of individual performance analysis.

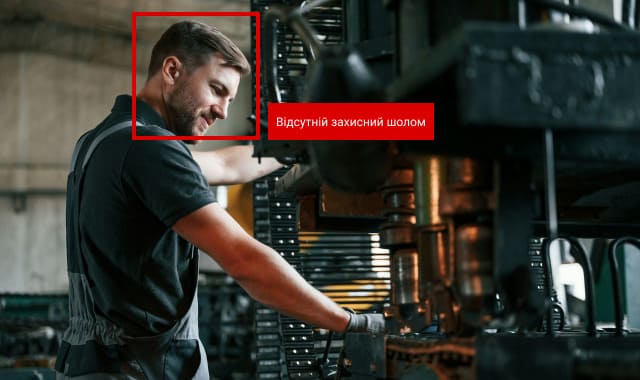

- Violations of occupational safety standards.

Objective

- Ensure automated access control and perimeter monitoring.

- Implement facial recognition for identifying employees and visitors.

- Monitor work processes and adherence to safety protocols.

- Prevent unauthorized access.

To address these tasks,

the ULA Video solution was implemented, which includes

the ULA Video solution was implemented, which includes

-

Facial RecognitionIdentifying personnel and controlling access to different enterprise zones.

-

Perimeter ControlDetecting unauthorized entry attempts or access to restricted areas.

-

"Friend or Foe" SystemAutomatically identifying employees and detecting outsiders on the premises.

-

Video AnalyticsMonitoring goods movement and ensuring compliance with occupational safety standards.

-

Emergency AlertsDetecting hazardous substance leaks, equipment malfunctions, and other emergencies.

Implementation Steps

-

Gathering client requirements and identifying critical tasks to enhance efficiency and safety.

-

Designing a solution tailored to client needs, including camera and sensor placement.

-

Configuring facial recognition and integrating with access systems

-

Installing video analytics for process monitoring

-

Implementing emergency alert features and integrating with other security systems (barriers, lighting).

-

Testing and optimizing the system.

Implementation Results

-

Enhanced SecurityMinimization of unauthorized entries, access control, and automatic violation detection.

-

Process OptimizationImproved resource allocation and reduced delays in production processes.

-

Loss MinimizationPrevention of theft and control of goods movement.

-

Quick Response to EmergenciesAutomatic alerts for hazardous situations.

-

Improved AccountingWork time control and staff schedule optimization.

The ULA system made manufacturing processes safer and more efficient.

Automation of monitoring and access control minimized risks, optimized resources, and increased productivity, paving the way for new project development.